China’s laser industry has a strong geographical distribution. The Pearl River Delta region represented by Shenzhen mainly uses medium and small power laser processing equipment, while the Central China region represented by Wuhan Optical Valley is on the product line. More comprehensive, covering large, medium and small power equipment. In addition to these two largest industrial clusters, the Yangtze River Delta, the Bohai Rim region, and the emerging Northeast Industrial Zone have all formed a relatively complete laser industry belt.

Industry upgrades laser processing equipment demand is greater

Where is the future of semiconductor lasers?

With the transformation and upgrading of the manufacturing industry to high-end and intelligent, the market for laser equipment processing and application has been expanding. Moore, one of the founders of Moore’s Law, made a prediction in 1965 that semiconductors will be developed at a high speed, and the electronic society will be widely popularized and penetrated into a wide range of applications. Looking back from half a century, this prophecy has long been perfect. Although the advantages of fiber lasers are huge, the semiconductor lasers are the most widely used on the market.

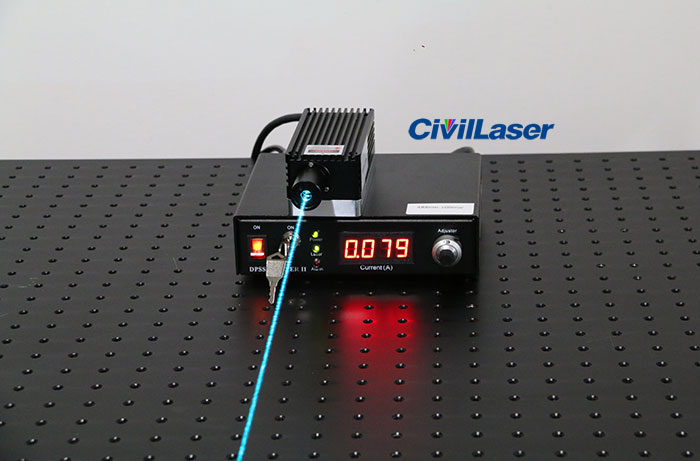

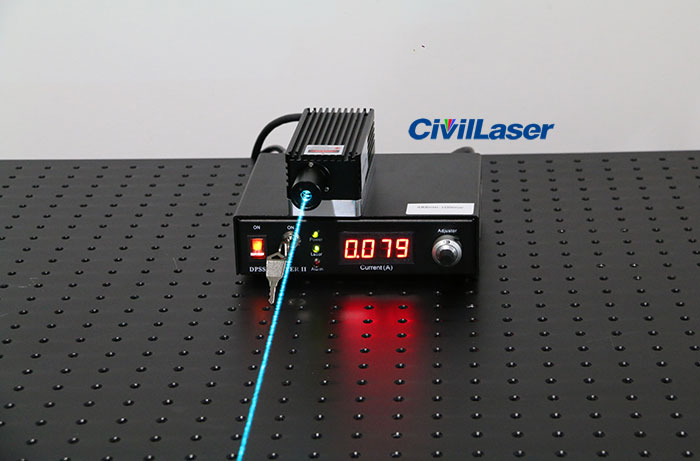

A semiconductor laser is commonly referred to as a laser diode, and is called a semiconductor laser because it uses a semiconductor material as a property of a working substance. Semiconductor lasers usually use gallium arsenide, cadmium sulfide, indium phosphide, etc., and can be used as a pump source for fiber lasers and solid-state lasers, or can directly output laser light as a light source.

The development of semiconductor lasers began in the 1960s and has now been widely used in various industries. With its compact structure, good beam quality, long life and stable performance, it has made great achievements in the fields of communication, material processing and manufacturing, military and medical. It is precisely because of the wide application field of laser equipment and the numerous industries involved, the market for semiconductor lasers is very large. According to data from the OFweek industry research, the market size of semiconductor lasers in 2017 reached 5.31 billion US dollars, a year-on-year growth rate of 15%, accounting for 40% of the total market share of lasers, is absolutely dominant.

Global semiconductor laser market size and growth rate in 2012-2017 (unit: billion US dollars)

Where is the future of semiconductor lasers?

Technology development

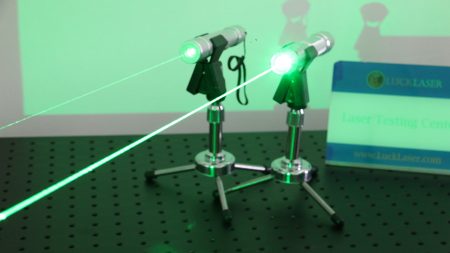

With the continuous development of semiconductor technology, market demand has been steadily turning. The field of semiconductor laser applications is also constantly changing. From the initial small power equipment to the current high-power equipment, semiconductor lasers have also shifted from some light processing fields to heavy processing fields.

As early as the 1980s, semiconductor lasers were only used in optical storage and in some niche applications. At the time, optical storage was the first large-scale application in the semiconductor laser industry. The continuous innovation of semiconductor laser technology has promoted the development of optical storage technologies such as digital versatile disc (DVD) and Blu-ray disc (BD). In the 1990s, optical networks became the main battlefield for semiconductor lasers. Later in the 1990s, semiconductor lasers became the key processing and manufacturing equipment for communication networks.

At present, the largest application of semiconductor lasers is as a pump source for fiber lasers and solid-state lasers. When the semiconductor laser is used as a fiber laser pump source, the structure of the pump system can be fundamentally simplified and the pump power level can be improved by increasing the unit power. As fiber lasers and solid-state lasers have higher and higher output power requirements, higher demands are placed on the power of semiconductor pump sources.

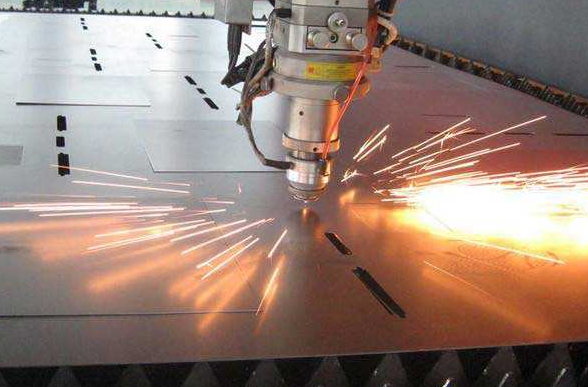

Conventional semiconductor lasers are difficult to use directly for metal cutting due to limitations in beam quality. In recent years, with the improvement of semiconductor coupling technology and the gradual maturity of new beam-combining technology, semiconductor lasers with output of some kilowatts or more of fiber can meet the requirements of cutting beam quality. In addition, due to the diversity of the wavelength of the semiconductor laser, the wavelength of the short-wavelength semiconductor laser is very close to the maximum wavelength absorption of aluminum. Therefore, in the automotive industry, high-power semiconductor lasers are very suitable for the welding of aluminum automobile bodies. At present, semiconductor lasers with laser output power between 2KW and 6KW have been widely used in the automotive industry.

In the field of direct processing of materials, the quality of semiconductor laser beams is difficult to exceed fiber lasers. However, semiconductor lasers are very suitable for thin-plate soldering and cutting applications. The development of high power semiconductor lasers has made many important applications possible. These lasers have replaced many traditional technologies and brought us many new products.

Summary: In general, due to the continuous development of technology, the application field of semiconductor lasers is constantly changing, and these changes are still happening. In general, semiconductor lasers are developing in the direction of shorter emission wavelengths and higher transmission power to meet current market demands.