Analyzing 40,000 watts: Problems still exist. What do you rely on to occupy the power high ground?

Manufacturing is the foundation of a strong country and the foundation of a rich country. Advanced manufacturing, especially high-end equipment manufacturing, has become the commanding heights of international competition. As an emerging intelligent manufacturing equipment, laser processing equipment can be regarded as the country’s most important. The laser is equivalent to the “heart” of laser processing equipment, which is particularly critical in the current international environment and is one of the driving forces of national industrial upgrading.

With the rapid development of high-end manufacturing, the laser industry has also ushered in the peak of development in the past decade. On the one hand, domestic laser processing equipment is rapidly maturing and new products are constantly being developed, and it has led the development of the global market in some areas; on the other hand, domestic low- and medium-power lasers have taken a dominant position in the market, and the technical level has been comparable to foreign products. Domestic substitution is almost complete. However, it must be admitted that in terms of high power, especially ultra-high power lasers, there is still a certain gap between domestic lasers and foreign products. The stability of higher power lasers is an urgent problem for domestic manufacturers to solve.

Can the 40kW multimode continuous laser occupying the high ground of laser power solve these problems? How to achieve a stable output of 40kW?

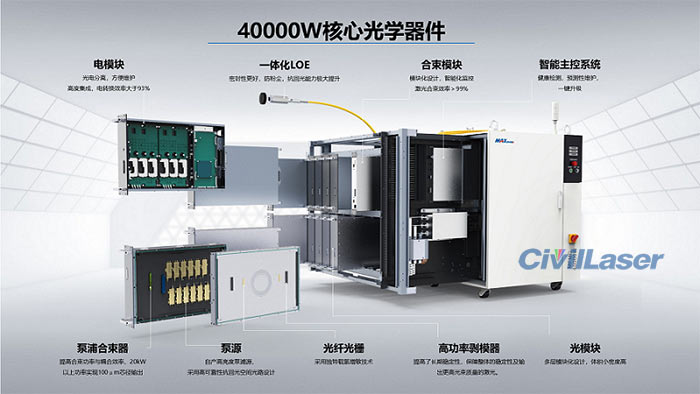

In an interview with OFweek Laser Network, Chuangxin Laser brand and market leader Zeng Jianfeng mentioned: “The release of 40kW is a true reflection of China laser’s core optical device independent research and development capabilities, and it also represents the current technical level of lasers in the ultra-high power field. We use domestic single-module beam combination with a maximum of 6kW, and combine our own technological breakthroughs and accumulations in core optical devices, such as high-power pumping technology, high-power stripper laser, high-power beam combiner technology, and third-generation integrated This technology is integrated into the 40kW product, which undoubtedly redefines the parameters of ultra-high power core devices. The breakthrough in these core optical device technologies is to ensure the stability of the laser key.”

In fact, Chuangxin Laser has repeatedly set new highs in laser power, which is inseparable from its strong technology accumulation in the field of devices. At the beginning of its establishment (2004), Chuangxin Laser mainly customized passive optical devices for scientific research institutes. The core technical personnel of the start-up team have more than ten years of optical device research and development experience. They are engaged in the cold processing of laser optical devices and optical raw materials upstream of the device. It has strong technical precipitation and industry resources. In 2008, Chuangxin Laser successfully developed and sold the first fiber laser, officially entering the fiber laser market. Since then, Chuangxin Laser has always adhered to the “device first” research and development strategy, using self-designed and produced optical devices to improve product consistency and stability, shorten the time for new product launches, and have more room for cost reduction. Enhance the competitiveness of the product market.

Ten thousand watt laser application: improving quality and efficiency to promote industrial upgrading

With profound technical background, Chuangxin Laser has seized the opportunity of the 10,000-watt laser market. Zeng Jianfeng said: “As of now, Chuangxin Laser has a total of more than 3 million watt lasers undertaking production tasks in the front line of various sheet metal cutting processing, and orders for more than 400 units, of which 20kW orders more than 50 units. The release of 40kW will definitely expand the sheet metal Gold cutting application space, undertake more arduous tasks.”

In 2017, the 10,000-watt laser cutting machine began to enter the market. In the following three years, the 10,000-watt market has developed rapidly. 12kW, 15kW, and 20kW have successively become the focus of the industry and continue to challenge the limits of laser cutting. Since the application of the 10,000-watt laser, it has completely subverted the traditional processing (even low- and medium-power laser processing) capabilities in terms of efficiency, quality and cost. It has greatly promoted the transformation and upgrading of the manufacturing industry and further improved my country’s high-end manufacturing industry. The competitiveness of laser equipment has promoted the rapid development of the laser equipment industry to ultra-high power.

In 2020, the new crown pneumonia epidemic will bring a major blow to the economy. After the epidemic, the country proposed an internal cycle to revive the domestic economy, and the two new economies (new infrastructure and new urban infrastructure) have become the key to boosting the economy. In this context, heavy machinery, urban rail transit, high-speed rail and new energy industries have strong manufacturing and processing demands, and “efficiency for efficiency” has become the overall demand of the industry.

Zeng Jianfeng believes: “The birth of 10,000-watt lasers has solved the contradiction between efficiency and quality. The laser industry has experienced several vicious competitions, and the gross profit rate of the whole industry has generally declined. End users urgently need higher efficiency, lower cost, and lower cost. High-quality equipment and tools. With the gradual popularity of 12kW and 15kW, 20kW enters the terminal, and 30kW has passed the supporting test and will be available soon. The 40kW complete cutting solution for efficiency will surely lead the new development trend.”

Strategic vision: Dare to be the first to promote the development of industrial chain linkage

At present, the most popular laser cutting market is the kilowatt-level equipment. The 10,000-watt laser cutting market is still in the development stage, and the 20kW application market is in its infancy. For equipment integrators, there are still many stability issues that need to be solved urgently, such as functional components, dust removal systems, water cooling systems, bed design, etc., which still need to be continuously tempered by the market.

The development limitations of supporting industries cannot limit the development of laser light source technology. As mentioned earlier, Chuangxin Laser has always adhered to the “device first” strategy, and its continuous technological breakthroughs in core optical devices are the key to supporting its continuous occupation of high power and ensuring high beam quality and high stability of the laser. In addition to the “device first” strategy, Chuangxin Laser has also implemented the “integration to win” development route and through standard output, assisting domestic device partners to jointly break through the ultra-high-power technical problems.

Zeng Jianfeng said: “This vertically integrated ecological chain model will promote the comprehensive upgrade of all upstream supplies including domestic chips and domestic optical fibers. At the same time, it will promote the laser cutting head, operating software, laser equipment system and other peripheral supporting equipment to keep up to date with Chuangxin Laser. The 10,000-watt laser products are closer. The 40kW brand-new technical solutions and parameter indicators bring an opportunity for win-win cooperation. This upstream and downstream linkage effect far exceeds the value brought by a single product release.”

With the completion of the 40kW joint release, it heralds a new journey for ultra-high power laser applications. The landing of 40kW and higher power laser products in the future will play a demonstrative and leading role in national manufacturing capacity and industrial transformation and upgrading. We dare to take the lead and keep advancing, which will inspire more like-minded people to help the development of China’s laser industry.